How do drone payload systems deliver supplies in a way that meets safety, cost, and time needs?

Drone payload systems deliver supplies

We use drone payload systems to move supplies by air. We rely on these systems to reach remote sites, lower costs, and speed delivery.

What is a drone payload system?

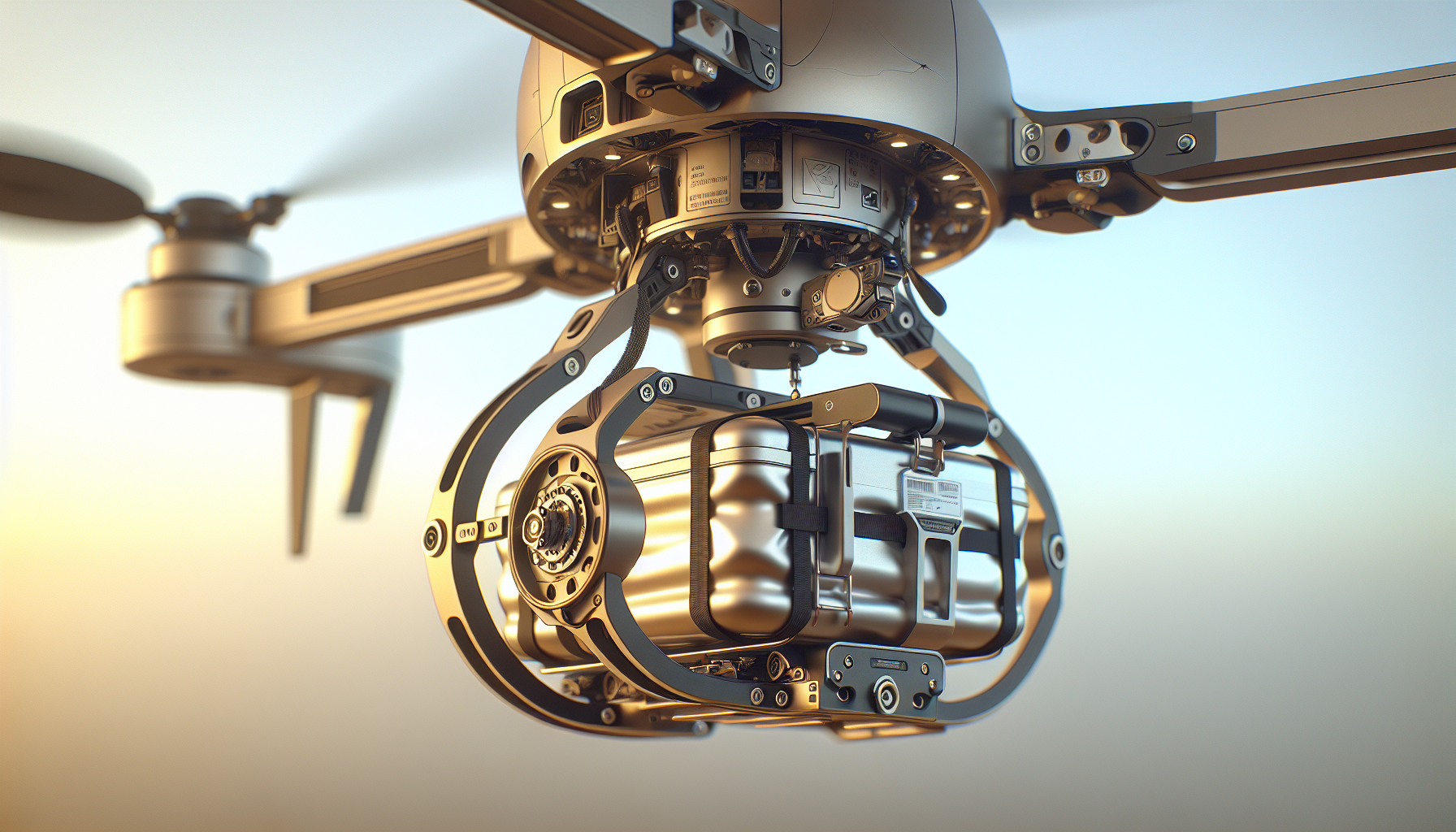

We define a drone payload system as the set of parts that let a drone carry and release cargo. We include mounts, trays, release mechanisms, sensors, and wiring in that set. We keep the design simple so operators can use it in the field with limited tools.

How payload systems work

We attach a payload to a drone at a secure point. We program the drone to fly to a location and to release the load by a planned method. We test the whole system before flight to reduce the risk of failure.

Payload attachment methods

We use hard mounts for rigid cargo and soft slings for variable shapes. We fasten mounts to the airframe at designed points that take the load without bending.

Release mechanisms

We use servo-based hooks, magnetic locks, and pyrotechnic cutters depending on mission needs. We choose the simplest reliable method that meets safety rules and mission constraints.

Weight and balance

We calculate the center of gravity and the total mass before each flight. We place the payload so the drone stays stable in flight and so the motors do not overload.

Types of payloads delivered

We move many types of payloads by drone. We focus on items that weigh within the drone capacity and that need fast or remote delivery.

Medical supplies

We carry vaccines, blood, and small medical kits. We keep the cargo temperature controlled when needed and we protect fragile items with foam or insulation.

Food and water

We move prepared meals, small food boxes, and water packs. We secure liquids to prevent spillage and we protect food from dust.

Commercial packages

We deliver e-commerce parcels and spare parts for industry. We log the package weight and dimensions before flight to plan the route.

Emergency equipment

We send sensors, blankets, radios, and life vests to people in crisis. We prioritize urgent and life-saving items for quicker dispatch.

Payload capacity and drone classes

We classify drones by their payload weight and range. We use small drones for light, local jobs and larger drones for heavier goods or longer distances.

| Drone class | Typical payload | Typical range | Typical use case |

|---|---|---|---|

| Nano | < 0.5 kg | < 2 km | Sensors, samples |

| Small | 0.5–5 kg | 2–20 km | Medical kits, parcels |

| Medium | 5–25 kg | 20–100 km | Bulk medical supplies, food boxes |

| Large | 25–200+ kg | 100+ km | Palletized goods, heavy equipment |

We choose a class based on load and distance. We plan flights to match the drone capabilities.

Delivery modes

We use several delivery modes based on landing availability and risk. We pick the mode that keeps people and cargo safe.

Airdrop

We release the package mid-flight for quick delivery when ground access is unsafe. We add parachutes or cushioning so the package arrives intact.

Landing

We land the drone on a clear surface and we unload the package manually or by a simple latch. We prefer landing when space and safety allow it.

Winch and lowered delivery

We lower the package on a cable when landing is not possible or safe. We keep the drone hover steady and we control the descent to a gentle stop.

Navigation and autonomy

We use navigation systems to move the drone to the drop point. We combine GPS, sensors, and flight logic to keep the route safe.

GPS and RTK

We rely on GPS for general positioning and on RTK for high precision. We switch to RTK when we need better landing or drop accuracy.

Obstacle avoidance

We use lidar, sonar, and vision cameras to see obstacles. We program the drone to slow, steer, or stop to avoid collisions.

Flight planning and waypoints

We build a waypoint plan that the drone follows. We include altitude, speed, and hold points to adapt to weather and traffic.

Safety and regulations

We follow safety rules to protect people and property on the ground. We meet the legal requirements for the airspace we fly in.

Airspace rules

We file flights where required and we get permissions for controlled airspace. We follow altitude and route limits that local authorities set.

Payload safety

We package items to prevent leakage, release, or sudden fall. We label hazardous goods and we follow transport rules for those items.

Privacy and data

We collect flight data for safety and records. We avoid recording private activities and we store only the information that we need.

Design considerations for payload systems

We design payload systems to be light, strong, and easy to swap. We plan each part for its role and for the environment it will face.

Weight minimization

We use light materials and we trim excess mass to improve endurance. We keep fasteners and parts to the minimum needed for safety.

Secure attachment

We use points that resist pull, shear, and vibration. We test attachments under load cycles to confirm they hold.

Aerodynamics

We shape payloads to reduce drag and to keep flow smooth. We put sensitive items inside the fuselage or under fairings when possible.

Materials and components

We select materials for strength and low weight. We choose parts that resist moisture and that meet the mission temperature range.

| Component | Role | Typical material |

|---|---|---|

| Mounting frame | Secure payload to airframe | Carbon fiber, aluminum |

| Release hook | Hold and release cargo | Stainless steel, composite |

| Enclosure | Protect cargo from weather | Composite shell, foam lining |

| Parachute | Slow descent in airdrop | Nylon, kevlar shroud lines |

| Winch | Control lowered delivery | Aluminum motor, steel cable |

| Sensors | Monitor weight and position | Load cells, IMU, GPS |

We pick each component to balance cost, weight, and reliability. We document parts so teams can swap them in the field.

Power and endurance impact

We measure how payload mass reduces flight time. We plan flights with safety margins so we can return with some battery left.

Battery choices

We choose high energy density batteries for longer range. We keep spare batteries and we rotate them to keep capacity high.

Power management

We calculate energy use for flight and payload operation. We schedule missions within the safe flight envelope and we reserve margin for contingencies.

Case studies and use cases

We present real use cases to show how payload systems perform. We focus on lessons that affect planning and hardware choices.

Medical delivery in rural regions

We supported clinics that lacked road access by sending vaccines and blood tests. We used small drones with temperature control and we delivered items within an hour of request.

We measured delivery time from dispatch to drop. We recorded improved care times and reduced spoilage.

Disaster response after storms

We supplied shelters with batteries, radios, and water packs after storms. We used winch drops to avoid rough ground and we kept the team safe while crews repaired roads.

We found that coordinating with local teams sped unloading and distribution. We kept arrival logs to track inventory.

Commercial last-mile trials

We ran trials for parcel delivery in suburban areas. We used small drones over fixed routes and we built simple ground stations for loading.

We recorded time and cost per delivery and we compared them to van routes. We learned that drones gave real time savings for urgent small packages.

Industrial spare part delivery

We delivered spare parts to remote oil sites and to mines. We used medium drones to carry critical components that would otherwise take days to ship.

We used charging hubs at forward bases to extend reach. We saved downtime and reduced the cost of emergency deliveries.

Economic and logistic benefits

We measure cost per delivery, time saved, and impact on supply chains. We often find that drones lower marginal costs for urgent or low-volume deliveries.

Cost per delivery

We calculate cost from energy, maintenance, operator time, and amortized purchase cost. We compare this to ground transport to decide when aerial delivery makes sense.

Speed and reliability

We plan routes that reduce travel time. We use redundancy and spare drones to keep service running during faults.

Challenges and limitations

We identify limits in weather, weight, and rules. We plan for these limits so missions do not fail.

Weather and environment

We avoid high winds, heavy rain, and icing that reduce safety. We build weather checks into the flight plan and we delay flights when conditions exceed thresholds.

Payload security

We secure packages against theft and drop. We audit chain of custody for sensitive items to show who handled the package.

Regulatory hurdles

We work with regulators to gain approvals for beyond visual line of sight and higher risk missions. We keep clear logs and we follow incident reporting rules.

Future trends

We track tech and policy changes that affect payload systems. We prepare the team and the hardware for likely advances.

Swarming and networked delivery

We foresee groups of drones working together to move larger shipments or to give redundancy. We design payload interfaces so drones can share loads safely.

Improved batteries and fuels

We expect batteries to reach higher energy density and to shrink in price. We plan for hybrid power options for very long missions.

AI and better autonomy

We use machine learning for route planning and obstacle avoidance. We keep human oversight in higher risk tasks and we log AI decisions for review.

Best practices for operators

We make checklists for preflight, flight, and post-flight tasks. We train teams to follow the same steps and to report issues quickly.

We inspect mounts every day that we fly. We replace worn parts and we keep spares on hand.

Maintenance and inspection

We schedule routine maintenance on motors, props, batteries, and payload mounts. We also plan periodic non-destructive tests on critical parts.

We log all maintenance actions and we use data to predict failures. We retire parts before they reach risk levels.

Payload integration workflow

We define a clear workflow for integrating new payloads. We check weight, center of gravity, electrical load, and release function.

We perform a ground test, then a tethered hover, and then a short flight before full mission flights. We record the results and we adjust the design as needed.

Ground handling and loading

We set clear procedures for loading and unloading in the field. We train ground staff to fasten cargo and to check seals and labels.

We use simple jigs and checks that anyone can follow. We keep the process repeatable to avoid mistakes.

Data collection and performance metrics

We collect time, battery use, drop accuracy, and incident reports. We use this data to improve routes, hardware, and training.

We analyze trends and we update maintenance schedules and flight rules based on the results. We share key metrics with regulators and partners.

Environmental and social impact

We measure how drone delivery affects local traffic, noise, and emissions. We seek to reduce fuel use and to lower the carbon footprint of urgent delivery.

We consult communities and we adapt flight paths to reduce noise near homes and schools. We build transparency into operations to build trust.

Training and human factors

We train pilots, ground crew, and maintenance staff in clear, task-based steps. We emphasize simple decisions under stress and we run drills for common faults.

We keep the human in the loop for final release decisions in higher risk cases. We maintain clear communication protocols for teams.

Insurance and liability

We work with insurers to cover damage, injury, and cargo loss. We document flights and maintenance to support claims and to reduce premiums.

We choose insurance policies that match the mission risk and we update them as operations scale.

Partnering with local services

We coordinate with local clinics, emergency teams, and logistics hubs. We share load forecasts and we align schedules to smooth pick-up and hand-off.

We build local capacity so communities can handle basic loading and distribution tasks. We offer training and we keep support lines open.

Procurement and supply chain for payload systems

We build a parts list and we choose suppliers with good delivery records. We prefer standard connectors and hardware so teams can source spares locally.

We plan for lead times and we keep a buffer of critical parts. We test alternatives to reduce single-source risk.

Metrics for mission success

We set clear targets for time, cost, and delivery accuracy. We use these numbers to decide if a route or payload system is ready to scale.

We revise targets as conditions change and as we gather more data. We communicate results to stakeholders in straightforward reports.

Scaling operations

We scale by increasing the number of drones, by adding hubs, and by automating routine tasks. We standardize hardware and software to keep complexity low.

We maintain safety and quality as the operation grows. We keep training and audits in place to avoid drift.

Open questions and research needs

We list areas where more data or better tech would help. We note battery improvements, better drop accuracy in wind, and clearer rules for urban airspace as priorities.

We invite tests and shared data across teams to speed progress. We keep the research focused on practical, field-driven outcomes.

Conclusion

We see drone payload systems as a useful tool for delivering supplies to hard-to-reach places and for speeding urgent deliveries. We design systems to be simple, safe, and repeatable so teams can rely on them in many conditions.